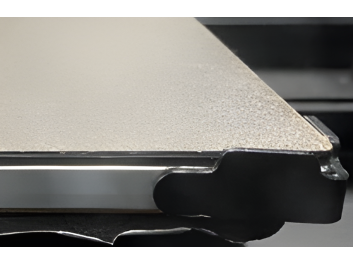

3DO PC-PBT 1KG - Carbon Fiber Polycarbonate

3DO PC-PBT-CF is a carbon fiber-reinforced composite filament that offers superior mechanical properties, including high tensile strength, stiffness, and impact resistance. This advanced material is lightweight, thermally stable, and exhibits low warping and shrinkage, making it ideal for demanding technical applications. A hardened nozzle is recommended due to the abrasive nature of the carbon fibers.

- High tensile and flexural strength

- Thermal resistance with a Vicat softening temperature of 130°C

- Low warping and shrinkage, ensuring precision

- Requires a hardened nozzle due to abrasive carbon fibers

- Nozzle: 265-295°C

- Heatbed: 110°C

3DO PC-PBT-CF is a carbon fiber-reinforced composite filament that combines the best properties of polycarbonate (PC) and polybutylene terephthalate (PBT) with the strength and rigidity of carbon fibers. This advanced material offers exceptional mechanical properties, including high tensile strength, stiffness, and impact resistance, making it ideal for demanding technical applications. The carbon fibers also provide a lightweight profile and enhance the thermal resistance, allowing for high-temperature applications without significant warping or shrinkage. A hardened nozzle is recommended due to the abrasive nature of the carbon fibers.

Key Features

- Excellent mechanical properties with high tensile and flexural strength

- High thermal resistance with a Vicat softening temperature of 130°C

- Outstanding chemical resistance, suitable for industrial use

- Lightweight and rigid due to carbon fiber reinforcement

- Low warping and shrinkage, ensuring precise and reliable printing

- Requires a hardened nozzle due to the abrasive nature of carbon fibers

Technical Specifications

| Property | Test Method | Unit | Value |

|---|---|---|---|

| Density | ISO 1183-1 | kg/m³ | 1200 |

| Melt Volume-Flow Rate (MVR) | ISO 1133 | cm³/10 min | 16 |

| Tensile Modulus | ISO 527-1,-2 | MPa | 4520 |

| Yield Strength | ISO 527-1,-2 | MPa | 70.2 |

| Yield Strain | ISO 527-1,-2 | % | 4 |

| Nominal Elongation at Break | ISO 527-1,-2 | % | >35 |

| Flexural Modulus | ISO 178 | MPa | 3350 |

| Flexural Strength | ISO 178 | MPa | 85 |

| Charpy Notched Impact Strength | ISO 179/1eA | kJ/m² | 65 |

| Puncture Performance - Maximum Force | ISO 6603-2 | N | 4400 |

| Puncture Energy | ISO 6603-2 | J | 47 |

| Vicat Softening Temperature | ISO 306 | °C | 130 |

| Heat Deflection Temperature (1.8 MPa) | ISO 75-1,-2 | °C | 89 |

| Heat Deflection Temperature (0.45 MPa) | ISO 75-1,-2 | °C | 115 |

| Linear Coefficient of Thermal Expansion, parallel | ISO 11359-1,-2 | 10-⁴/K | 0.9 |

| Linear Coefficient of Thermal Expansion, perpendicular | ISO 11359-1,-2 | 10-⁴/K | 0.9 |

| Flammability UL 94 (1.5 mm) | UL 94 | Class | HB (Bayer) |

Storage and Shelf Life

Store 3DO PC-PBT-CF in a dry room at room temperature (18-27°C / 65-80°F), away from direct heat and sunlight. Proper storage ensures the material retains its quality for up to 2 years.

Compliance and Additional Information

3DO PC-PBT-CF is compliant with relevant industry standards, ensuring safety and reliability in various applications. For more detailed information, please refer to the technical data sheet.