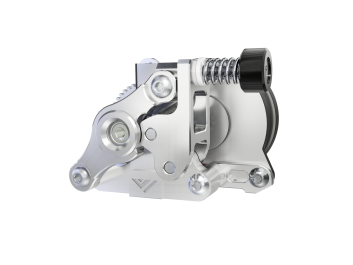

LDO Orbiter V2 Dual Drive Direct Extruder

Introducing the LDO Orbiter V2 Dual Drive Direct Extruder, a revolutionary 3D printer component designed by Dr. Lorincz Rober and manufactured by LDO. This powerful extruder is lighter, more compact, and offers a significant increase in push-force thanks to its innovative motor design.

- Its shortened drive gear (11mm vs 15mm) and hardened filament drive gear by Bondtech ensure superior performance.

- With a weight reduction to ~135 grams and dimensions 11.6% shorter, it offers greater convenience and ease of use.

- The flipped drive gear design brings the filament path closer to the extruder's center, providing a balanced design and perfect fit for delta printers.

- The stainless steel filament output guide with 0.2-0.3mm clearance ensures optimal TPU printing experience and extreme durability with abrasive filaments.

- High-temperature resistant injection housings (GPA12) and machine-machined PEEK secondary drive gear bushing further enhance its durability and functionality.

Designed by Dr. Lorincz Rober and produced by LDO

Shorter drive gear11mm vs.15mm

Hardened filament drive gear made from Bondtech

Weight reduced to ~135 grams

Smaller more compact dimensions (11.6% shorter)

New engine design offers ~40% increase in push power under right printing conditions and much improved acceleration performance

Flipped drive gear – filament track closer to the center of the extruder for a more balanced design and perfect fit also on delta printers

Stainless steel filament output handlebars with 0.2-0.3mm clearance to power gears for the best TPU printing experience and extreme durability using abrasive filaments.

High temperature resistant injection housings, GPA12

Machine-worked PEEK secondary drive gear bushing

Tension mechanism with gripper screw design (Captive Grab Screw)

Mounting screws in line with the filament exit road – improve the rigidity of the housing and easier installation

Perfectly aligned filament course

New smaller and better PTFE inputs

Engine position rotated another 10 degrees for easier maintenance and installation

Filament sensor is added with automatic loading and unloading add-on

And many more small changes to improve mechanical accuracy and design appearance