Shopping Cart

Bondtech CHT BiMetal MK8 Coated Nozzle

Copper and Hardened Vanadium Steel nozzle for high flow applications with abrasive materials.

Nozzle is supplied with Nickel Coating.

Increase the Max Volumetric Flow of your MK8 style heat block by 50%

They are manufactured by Bondtech in-house

Subscribe To When In Stock

You have successfully subscribed to this product

ALERT : Avoid Cold Change Of Bondtech CHT Nozzles

Heat up the heat block up to 280C, or at least above 250C, before removing or tightening any Bondtech CHT nozzle. Use at most 1.5 Nm torque.

ALERT : Size limitation for fiber loaded filaments

For Carbon or Glass fiber loaded abrasive filaments use only 0.6, 0.8 and 1.0mm nozzle size.

Bondtech CHT BiMetal MK8 Coated Nozzle Features

-

- Copper body;

- Hardened Vanadium Steel inserts;

- Nickel Coating;

- 1 unit per pack;

- Available sizes : 0.40, 0.60, 0.80, and 1.0mm;

- Optimized for 1.75mm filament;

- Compatible with 2.85mm filament.

- Requires 6mm wrench

Bondtech CHT BiMetal MK8 Coated Nozzle Advantages

- Abrasive-proof to work with Carbon and Glass fiber composite materials;

- Higher melt capacity by increasing the surface area of the heating walls

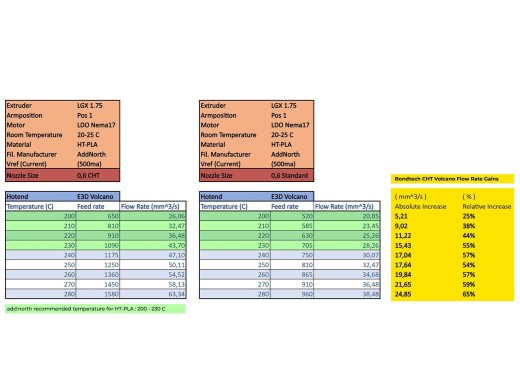

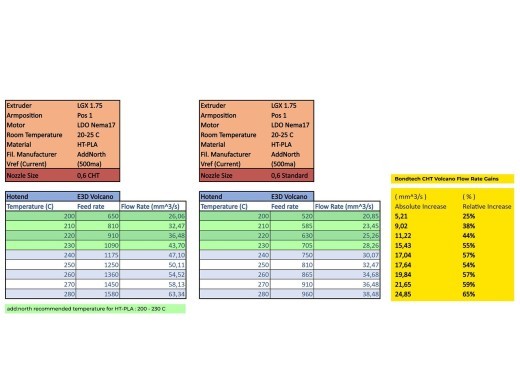

- Flow Rate gains between 25 and 65% (check picture with test data)

- Competitive price/performance price

- Machined with ultra-precision

- Copper body and Hardened Vanadium Steel inserts nozzle with Nickel coated surface

- Follows nozzle standard:

- MK8 (M6×1×5×13)

- May be used with 1.75 or 2.85mm hotends.

Flow Rate gains may vary. Results depend on the hardware, materials and print settings used.